Customized Multistage Cold Forming Parts

Customized Multi-stage Cold Formed Hardware Parts, Metal Fasteners

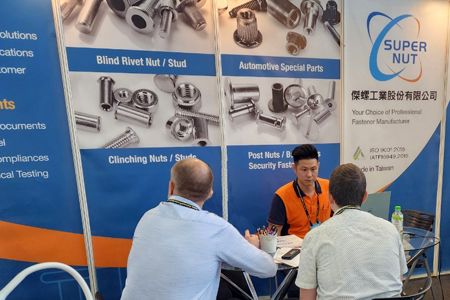

Customized Multistage Cold Forming Parts are Super Nut's production advantages. Blind rivet nut, male and female sleeves, six bolts and binding post screws, and internally threaded metal fasteners can all be customized.

Over 40 Years of Multistage Cold Formed Metallic Fastener Manufacturing Expertise

With over 40 years of experience in manufacturing rivet nuts, internally threaded metal fasteners, and hardware fasteners for export, Super Nut excels in the development and production of multistage cold formed metallic fastener products.

Our biggest strength is developing processes based on customized fasteners such as blind rivet nuts, sex bolts (barrel nuts and bolts), pipe threads…, etc.

Advanced Production Techniques and R&D

We are equipped with 5-die and 6-die cold-formers capable of producing high-precision, high-stability, and high-capacity multistage cold formed metallic products. The dedicated R&D technical team possesses customization capabilities, conducting assessments based on customer drawings, developing and designing molds, and creating complex-shaped fastener products.

Quality Assurance and International Standards

Certified per IATF 16949:2016, Super Nut has capability to utilize IATF core tools-APQP, FMEA, MSA, SPC, PPAP, and Control plan, to ensure the whole production and inspection process is well-controlled and managed systematically. Therefore, we are able to provide parts with high quality criteria and competitive prices, to create profit for both sides. For customers who need shorter lead time, we can offer safety stock upon conditions.

Versatile Manufacturing and Material Customization

Super Nut has the capability to manufacture hardware fasteners in various shapes to meet diverse client needs. We cater to specific material, surface treatment, and hardness requirements as per customer specifications and needs.

Over 40 years in fastener manufacturing with internationally certified quality management, serving various industries.

Super Nut has over 40 years of extensive experience in manufacturing rivet nuts, internal threaded metal fasteners, and multistage cold-forming fasteners. Our sales footprint spans across Asia, Americas, Europe, and the Middle East. Our product range covers wide range of industries including, automotive, electronic, architecture, furniture, naval architecture. We continue to work strictly under ISO-9001 & IATF-16949 management system to maintain our eligibility in OEM and Automotive business.

Development of Customized Hardware Fastener Cases

This customer is a Second - Tier automotive supplier, located in the most well-known Automotive...

DetailsSuper Nut Helped Customer to Solve the Issue of Concentricity Offset

This customer has been our valued business partner for over 10 years. They are a well-known...

DetailsSolves the Challenge Of Manufacturing Screws that are Difficult to Produce Due to Deformation

This project is a screw type of product with a bigger head dimension in proportion. In the cold-forming...

DetailsSuper Nut adheres to IATF16949 and ISO 9001 Protocols, Earning Trust and Winning a Key Project with Japanese Customers

This customer is an authorized Sony distributor in Japan, covering nearly all of Sony's electronic...

DetailsSuper Nut Performs Technical Professions to Help Customers Solve Product Assembly Issues

We met this customer at a Fastener Fair in the USA. They specialize in stamping parts production...

DetailsCustomized Multistage Cold Forming Parts | Advanced Rivet Studs for Industrial Applications | Super Nut

Super Nut is a leading manufacturer specializing in high quality multi-stage cold forged fasteners and hardware products. With a robust product line that includes Customized Multistage Cold Forming Parts, rivet nuts, rivet studs, sleeve nuts and blind rivet studs, we serve a diverse range of industrial needs worldwide. Our commitment to excellence and innovation ensures reliable, precision engineered fastening solutions that meet the highest standards. Trusted by businesses around the world, Super Nut continues to set the standard in the fastener industry by providing unparalleled product quality and customer service.

Super Nut was founded in Changhua, Taiwan. The company primarily serving in the Industrial fastening for both OEM and aftermarket , which includes in the sectors of Automotive, Electronics, Home Appliances and Constructional use. Combined with powerful capacity, our production specialty includes Rivet Nut production, Multistage cold forming parts, Clinching parts, or any sort of fasteners that are applied in the installation process.

Super Nut has been providing customers with environmentally friendly fastener solutions since 2009, with both advanced technology and 35 years of experience, Super Nut ensures that each customer's needs are met.