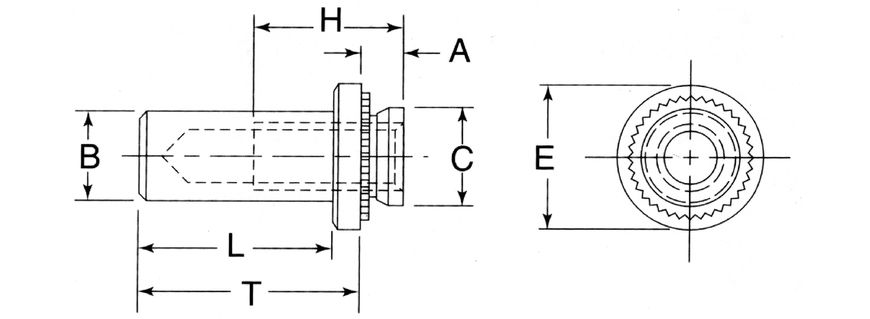

Self-Clinching Blind Pressed Nut

Pressed Clinching Nut

The blind pressed clinching nut can be pressed into thin panels to provide extended thread length in sheet metal. The blind hole feature also provides a seal against the entrance of dirt, particles, oils, moistures and corrosive atmosphere. They are usually more economical to use than mut and screw type hardware.

Self-Clinching Blind pressed Nut is available in customized specs (materials, finish, hardness, etc.) accordingly.

Features

- Self-Clinching Blind pressed Nut widely applied in various industries.

- High torque-out and push-out resistances.

- Excellent Corrosion Resistance.

- Competitive Price.

- RoHS / Reach Compliance.

- Customized Packing.

Specification

- Material: Steel / Stainless Steel

- Finish: Zinc Trivalent Plating / Zinc-Nickel Trivalent Plating

- Available in other specs (materials, finish, hardness, etc.).

- Spec

CP 4 Blind Pessed Nuts

Dimensions & Specifications (Millimeters) Thread Size Barrel

Dia.

B

Max.Sheet Thickness

Min.Hole Size

+0.08

-0.00Shank

Dia.

C

Max.L

Max.A

Max.E

+0.25

-0.25T

+0.25

-0.25Dis. Hole to Edge

Min.H

Depth

Full Thread Min.M3X0.5 3.8 1.0 4.25 4.22 8.5 0.97 6.35 9.6 4.8 5.3 1.4 1.37 M4X0.7 5.2 1.0 5.40 5.38 9.8 0.97 7.95 11.2 6.9 7.1 1.4 1.37 M5X0.8 6.0 1.0 6.40 6.38 9.8 0.97 8.75 11.2 7.1 7.1 1.4 1.37 M6X1.0 7.8 1.4 8.75 8.72 12.7 1.37 11.10 14.3 8.6 7.8 2.3 2.21 Dimensions & Specifications (Inches) Thread

SizeBarrel

Dia.

B

Max.Sheet Thickness

Min.Hole Size

+0.003

-0.000Shank

Dia.

C

Max.L

Max.A

Max.E

+0.01

-0.01T

+0.01

-0.01Dis. Hole to Edge

Min.H

Depth

Full Thread Min.#4-40 0.149 0.040 0.166 0.165 0.335 0.038 0.25 0.38 0.19 0.21 0.056 0.054 #6-32 0.169 0.040 0.187 0.186 0.335 0.038 0.28 0.38 0.22 0.23 0.056 0.054 #8-32 0.204 0.040 0.213 0.212 0.385 0.038 0.31 0.44 0.27 0.28 0.056 0.054 #10-32 0.235 0.040 0.250 0.249 0.385 0.038 0.34 0.44 0.28 0.28 0.056 0.054 1/4-20 0.305 0.056 0.344 0.343 0.500 0.054 0.43 0.56 0.34 0.31 0.090 0.087 * Material: Steel, Stainless Steel.

- Spec 1

Installation & Performance Data (Millimeters) Cold - Rolled Steel 5052-H34 Aluminum Thread Size Min. Installation

Force

(kN)Pushout (N) Torque-Out (N.m) Installation

Force

(kN)Pushout (N) Torque-Out (N.m) M3X0.5 1.0 11 560 1.5 7 440 1.4 M4X0.7 1.0 15 660 3.4 9 490 2.8 M5X0.8 1.0 17 620 4.0 10 490 3.8 M6X1.0 1.6 25 1780 11.9 18 1400 11.3 - Spec 2

Installation & Performance Data Cold - Rolled Steel 5052-H34 Aluminum Thread Size Min. Installation

Force

(LBS.)Pushout (LBS.) Torque-Out (IN.-LBS.) Installation

Force

(LBS.)Pushout (LBS.) Torque-Out (IN.-LBS.) #4-40 0.040 2500-2700 125 13 1500-1600 100 12 #6-32 0.040 3000-3100 130 38 1850 105 17 #8-32 0.040 3400-3600 135 30 2000 110 25 #10-32 0.040 4000 140 35 2100 110 34 1/4-20 0.062 6000 400 105 4000 315 100

Self-Clinching Blind Pressed Nut | Reliable Fastener Solutions | High-Quality Blind Rivet Studs

Super Nut is a leading manufacturer specializing in high quality multi-stage cold forged fasteners and hardware products. With a robust product line that includes Self-Clinching Blind Pressed Nut, rivet nuts, rivet studs, sleeve nuts and blind rivet studs, we serve a diverse range of industrial needs worldwide. Our commitment to excellence and innovation ensures reliable, precision engineered fastening solutions that meet the highest standards. Trusted by businesses around the world, Super Nut continues to set the standard in the fastener industry by providing unparalleled product quality and customer service.

Super Nut was founded in Changhua, Taiwan. The company primarily serving in the Industrial fastening for both OEM and aftermarket , which includes in the sectors of Automotive, Electronics, Home Appliances and Constructional use. Combined with powerful capacity, our production specialty includes Rivet Nut production, Multistage cold forming parts, Clinching parts, or any sort of fasteners that are applied in the installation process.

Super Nut has been providing customers with environmentally friendly fastener solutions since 2009, with both advanced technology and 35 years of experience, Super Nut ensures that each customer's needs are met.